| DE | EN | Contact | About us | Terms of Business | Imprint | Privacy & Cookies | Help | Newsletter | Registration | Login | |

|  |  |  |  |  |  |  |  |  |  |  |

| Home > News > Case Studies > Power Supplies > How do LED drivers work in constant power mode? | |||||||||||

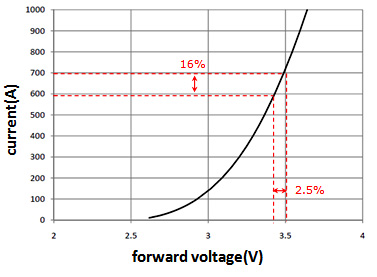

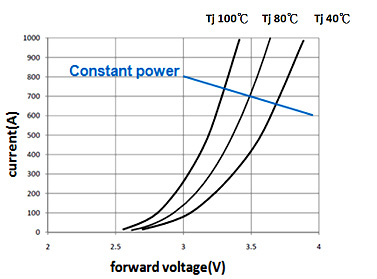

How do LED drivers work in constant power mode?Schukat presents an alternative to operating LEDs with constant currentControlling LEDs in constant power mode is currently a topic of much discussion. At the same time, the basic question remains: do LEDs always have to be operated with constant current or not? We address a number of questions on the subject: Why must an LED be operated with constant current?The current through the LED changes by 16% (see example at figure a, LED I-V curve) in response to a change in the LED forward voltage (UF) of around 2.5%. At the same time, the LED junction temperature strongly affects UF. High temperature fluctuations can lead to a voltage change of up to 20% or more. The brightness of the LED is proportional to the flow of current through it. If this current fluctuates greatly, the same happens to the brightness. It is therefore necessary to control the LED with a constant current source. Can an LED also be operated with constant power?We have to put aside for a moment the question of whether constant power means the same as constant brightness. According to I-V and the LED temperature curve, the design of a constant power driver seems to function. Why don't all manufacturers develop constant power LED drivers?Developing a driver with a constant power design is simple. A prerequisite is the implementation of a microcontroller (MCU) in the LED driver. The task of the MCU is to control the output power via a PWM (pulse width modulation) duty cycle. To control this, the microcontroller has to evaluate the feedback signal from the output voltage and output current, and control the output in such a way that a constant power characteristic is achieved (see figure b).

Note:• A constant power driver is more expensive to produce than a constant current driver.

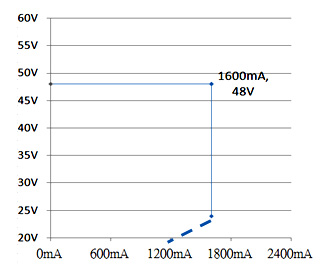

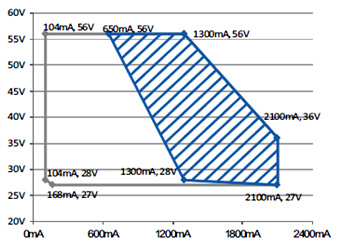

• The output current increases with the potential failure of one or more LEDs and the reduction in voltage drop across the LEDs that results. This can exacerbate the failure situation in the lamps. Why are constant current LED power supplies a good choiceDeploying an LED driver with a broad spectrum of output voltage and current, taking all factors into account, is the most effective solution. Effective constant power LED driversMEAN WELL has developed constant power drivers with a wide range of voltage and current. It is no longer necessary to provide different constant current drivers, and by avoiding superfluous power reserves, unnecessary costs can be circumvented. What's more, the option of manually limiting the output current means that damage to the lamp caused by excessive current can be prevented. Schukat electronicThrough Schukat, you can obtain the entire XLG series from MEAN WELL, which feature the constant power design. The advantages: • Wide range of output voltage and current for flexibility and efficiency when configuring different LEDs.

|

|