|

Heat dissipation in tight spaces Schukat recommends the advanced solution offered by compressible pyrolytic graphite sheetsThermal management and cooling in very tight spaces poses challenges for developers of electronic equipment and systems. One solution is Soft-PGS offered by Panasonic, an excellent solution especially for IGBT modules. The problem

With the trend towards miniaturisation, many electronic devices now have very limited space available. Even complex electronic systems are being built into smaller and smaller enclosures. Consequently, when it comes to conducting away and distributing the generated heat, new solutions are required for the various areas of application – whether for Industry 4.0, electric and hybrid cars, modern medical devices or solar panels. Solution and example

In response to this problematic, Panasonic has developed its pyrolytic graphite sheets (PGS) – an ultralight material also available in the Soft-PGS version. At just 10µm to 100µm thick (PGS) or 200μm thick (Soft-PGS), these sheets are currently the thinnest thermal solution in the world. Thanks to their outstanding thermal conductivity, they offer efficient heat distribution in compact electronic equipment.

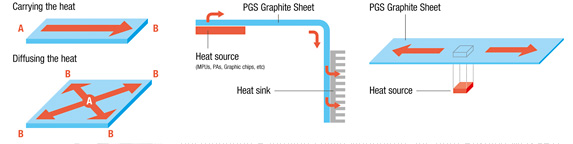

PGS can be utilised in various ways:

• In electronic equipment, it is crucial to conduct heat away from heat sources and to avoid hotspots (heat gathering at a central point). Everywhere that heat is generated quickly, PGS conducts it away quickly and effectively.

One example: In the integrated circuit of an LED application, PGS conducts the heat out to the enclosing case, where it spreads evenly over a larger surface area and is then radiated away.

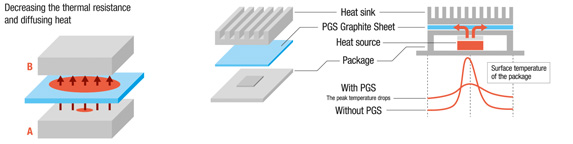

• With IGBTs or MOSFETs, PGS functions as a heat interface that protects the components from damage. To conduct away the generated heat and give it up to the surrounding environment, the IGBTs and MOSFETs are mounted on heat sinks. The components thus maintain relatively low operating temperatures and deliver optimal performance. To minimise thermal resistance between the base plate and the heat sink and to ensure good thermal conductivity, engineers us a thermal interface material. Soft-PGS can function as an alternative to specialised adhesives and pastes, overcoming potential air-gaps and thermal resistances.

Panasonic's PGS works like this:

• The synthetic film is produced from a polymer with extremely high thermal conductivity, from 700 to 1,950 W/mK. That is five times better than copper and seven times better than aluminium. Compared with other silicone and graphite products, PGS demonstrates considerably lower thermal resistance.

• The film sections are highly adaptable and wear-resistant: They can be curved back 180 degrees around a bending radius of 2mm, and can withstand up to 3000 bending cycles. If necessary, the film sheets – thanks to the hexagonal structure of a crystal and the two-dimensional carbon matrix – can be cut to size, bent into complex three-dimensional shapes and simply glued to the heat source.

• The Soft-PGS provides even better adaptability to uneven and rough surfaces: using a sintering process and compared to regular PGS, a much bigger layer with hollow spaces is created, allowing a significantly higher compression of up to 40%. As a thermal interface material, Soft-PGS was developed primarily for IGBT modules, reducing the thermal resistance in very limited space.

Schukat offers a range of standard Soft-PGS films for various IGBT modules from different manufacturers. Regular PGS is available as graphite sheets with and without a heat-stable adhesive. The PET tape is suitable for applications requiring higher insulation. Your Schukat sales team will be happy to answer any other questions you may have about the material and how to use it.

|

|

|