| DE | EN | Contact | About us | Terms of Business | Imprint | Privacy & Cookies | Help | Newsletter | Registration | Login | |

|  |  |  |  |  |  |  |  |  |  |  |

| Home > News > Case Studies > Passive and Electromechanical > The patented coating process for EMC shielding for shielding effectiveness of 99.999999% up to 105db | |||||||||||

The patented coating process for EMC shielding for shielding effectiveness of 99.999999% up to 105dbSchukat talks about the high-efficiency shielding technology for industrial enclosures

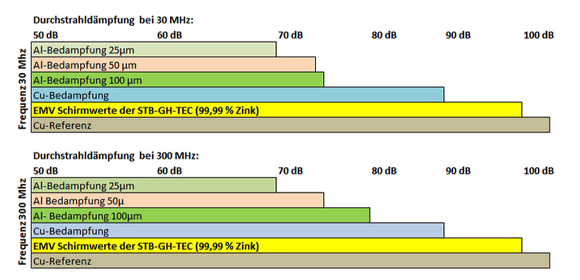

The patented coating process for EMC shielding from STB-Abschirmtechnik GmbH, designed for industrial enclosures, features the best attenuation results currently available, along with excellent bonding, shielding and conductivity values - it achieves a maximum shielding effectiveness of 99.999999% up to 105db.The problemIndustrial enclosures have to find the right balance between suitability for industrial use, low weight and affordable prices. Because electromagnetic radiation occurs in numerous applications, the devices here require a high level of shielding (EMC). But until today, solutions that offered high EMC protection also had crucial disadvantages: either they suffered from being too heavy, e.g. when using a metal case, or, as a plastic case, they did not provide enough shielding. In addition, there were small batch sizes, high human resources costs and no repeatability, because the coating process was carried out manually – all of which added up to inflexibility. The solutionThe newly developed, patented process for EMC shielding from STB-Abschirmtechnik GmbH offers the solution: Plastic electronic enclosures with internal metallisation provide for protection from both low-frequency and high-frequency radiation. Moreover, they can now be ordered “off the shelf” from Schukat. How the coating process works• The coating adheres mechanically and practically indissolubly with the substrate: initially, a heterogeneous metal surface is created, and in the course of the process this bonds to form a fully metallic metal layer up to 120µ thick, which even allows solder joints (for ESD dissipation) to be placed.

• Other suppliers, by contrast, process the substrate with either thermal or chemical treatments, resulting in poorer bonding, substrate deformation, reduced shielding effectiveness, and sensitivity to external influences.

► NoteEMC protection is given too little attention by many companies, especially small and medium-sized enterprises, and their products often do not meet the necessary requirements. In 2016, the EMC Directive 2014/30/EU increasingly brought radiation protection for industrial enclosures into focus. According to the VDE, the reason for the extensive adaptation of the directive was the reciprocal electromagnetic interference between systems and the potential for associated hazards: in a serious situation, an electromagnetic disturbance can lead to total system failure, resulting in high property and financial damage. External influences and attacks are also playing an increasing role, whether from interfering signals, eavesdropping, or data theft. Early EMC protection is therefore indispensable. At SchukatAt Schukat electronic we offer a wide range of electronics enclosures with internal metallisation from STB-Abschirmtechnik GmbH. This electronics enclosure system has been firmly established on the market for 30 years. Employing a tongue-and-groove system, it is highly impact-resistant, splash-proof, and particularly robust. The manufacturer also uses stabilisers on the inside and tensions the casings after spraying. This prevents warping during cooling and ensures excellent fitting accuracy — a plus when compared to mass-produced goods. While there are currently two different enclosure domes for PCB mounting in the standard range, the circuit board mounts can also be customised and adapted to suit different PCBs.

|

|