| DE | EN | Contact | About us | Terms of Business | Imprint | Privacy & Cookies | Help | Newsletter | Registration | Login | |

|  |  |  |  |  |  |  |  |  |  |  |

| Home > News > Case Studies > Passive and Electromechanical > Mastering miniaturisation with hybrids | |||||||||||

Mastering miniaturisation with hybridsThe advantages of polymer hybrid capacitors in demanding applications

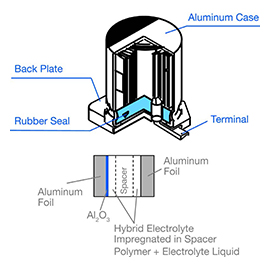

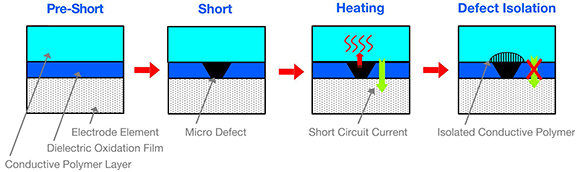

Great performance, small footprint, outstanding reliability, and a high level of safety – these four attributes are crucial in industrial environments, particularly the automotive sector. Schukat sums up why polymer hybrid capacitors might just be the perfect choice.The problemAdvances in the IIoT, process digitalisation, and automation demand the increasing integration of electronics into industrial applications. Key factors driving the need for more robust capacitor solutions are maximum reliability and the stable performance of all components. Conventional capacitor technologies are less than ideal for applications in challenging operating environments and may even pose a significant safety risk. Disadvantages of traditional capacitors• Premature failure caused by liquid electrolyte drying out The solutionPolymer hybrid aluminium capacitors bring together liquid, conductive polymers as an electrolyte with an aluminium cathode. This technological approach combines a number of advantages. The polymer offers high conductivity and a correspondingly low ESR value. The liquid component of the electrolyte, on the other hand, can withstand high voltages and offers higher capacitance values due to its large effective surface area. The voltage range of the hybrid capacitors is from 25 to 80V, with capacitance values between 10 and 1000μF. And while the ESR values of 8 to 120mΩ are higher than in other polymer capacitor variants, they are still very low.

Hybrid models are ideal for applications in computer services, backup devices, networking equipment, industrial motors, automotive engine control gear, inverters, security cameras, and specialty lighting. Advantages of polymer hybrid capacitors• Outstanding frequency characteristics: The low ESR values ensure low impedance close to the resistance point, reducing AC ripple in circuits.

Optimised Total Cost of Owners (TCO)All together, these properties point to a clear overall cost advantage when using hybrid capacitors, despite their higher price point. The higher ripple current specification alone, with the extended service life of the capacitor, can lead to cost reductions of 20 percent. At SchukatAt Schukat electronic, we offer fast, competent support when selecting the capacitors best suited to your application. With our inventory of Panasonic polymer and hybrid capacitors, we support the realisation of automotive and industrial applications with the highest levels of reliability and safety, as well as an economically attractive TCO. Working with Schukat means personal, specialist contacts, a swift response to enquiries, and the provision of data sheets and samples. From our automated logistics centre in Monheim am Rhein, we ensure high availability at short notice to cover your needs – for high volumes, too. Our sales team can advise on selecting the right component and on customer-specific questions relating to capacitors. |

|