| DE | EN | Contact | About us | Terms of Business | Imprint | Privacy & Cookies | Help | Newsletter | Registration | Login | |

|  |  |  |  |  |  |  |  |  |  |  |

| Home > News > Case Studies > Power Supplies > Why EV chargers need auxiliary power busbars | |||||||||||

Why EV chargers need auxiliary power busbarsComplex demands placed on auxiliary power supplies

DC charging of electric vehicles is an emerging market with special technical requirements. While the development of mains power conversion technology is well advanced, there is a need for low power AC/DC and DC/DC auxiliary power supplies.BackgroundThe number of installed chargers for electric cars is growing exponentially. At the same time, the complexity of the chargers in use is high, ranging from a slow, simple, single-phase household AC source for on-board charging to ultra-fast DC chargers of 800V or more, powered by a three-phase AC supply and equipped with multiple processors and interfaces. In addition, for each DC charger, a series of low-power auxiliary busbars should be used.

Although a multi-kW mains power supply can also generate direct current with low power – e.g. from a winding of the PFC inductor – there are a number of reasons why this is rarely useful:

• Efficiency: The mains power supply of the DC charger, when not under load, causes considerable losses. At their typical operating values, low-power AC/DC power supplies offer high efficiency. The challengeAC/DC and DC/DC auxiliary power supplies in DC chargers have to be in accord with special environmental requirements. A long service life and high reliability coupled with industrial quality parts are basic requirements. Moreover, certain standards still have to be met:

The solutionRECOM offers a range of standard products that meet the complex requirements of DC chargers for low-power electric vehicles and which are also suitable for many other applications.

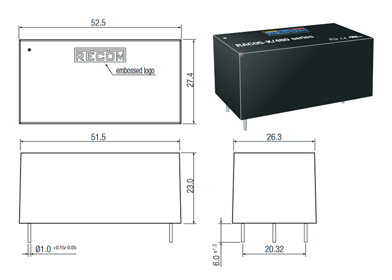

Among their standard products are the encapsulated miniature modules in the RAC series, rated from 3W to 40W, which are suitable for environments with a high level of contamination. In addition to the “standard” input range of 85-264VAC, some variants are designed for 305VAC for 277VAC nominal. The RAC05-K/480 is even designed for an input of up to 528VAC (Figure 2). The operating temperature range of all modules is from -40°C to +80°C, and all are available with OVC III approval either as standard or optionally. The safety certification of all these RECOM modules is comprehensive, with IEC/EN 62368-1 being the minimum – some even meet IEC/EN 61558 or EN 60335-1 for domestic use or even IEC/EN 60601-1 for medical applications.

What’s more, the RECOM range encompasses a broad selection of DC/DC power supplies suitable for gate drive power for the mains power supply, and for isolated communications interfaces, isolated auxiliary busbars and non-isolated point-of-load power supplies. All of these power supplies are designed for use in demanding environments. At SchukatSchukat offers power supplies from RECOM and other manufacturers. Schukat stocks around 6000 different types of power supplies and DC/DC converters in production quantities at its automated central warehouse in Monheim am Rhein, Germany.

As a distributor, we provide fast, competent support with direct contact persons in-house, and also have an expert field service team for on-site problem solving. Customers benefit from rapid processing of inquiries, availability of data sheets and samples, and variable delivery quantities – from samples to series production. |

|