Situation

In many applications, temperature measurement is one of the most problematic processes. In the automotive industry, demand for NTCs has grown for applications including control units, electric pumps and compressors, LED lamps, batteries, audio systems, and alternative drive systems, amongst others. They are also used in industrial and domestic applications, e.g. for circuit compensation, in control applications and in battery management systems.

Solution and advantages

While the manufacture of precision thermistors was previously labour-intensive and time-consuming, Panasonic has succeeded in producing low-cost, replaceable glass thermistors on extremely stable, high-precision NTC chips.

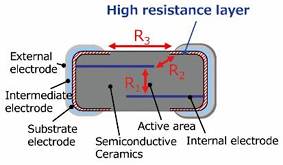

These thermistors offer long-term reliability and stability and are suitable for use in harsh environments and in challenging thermal conditions. In addition, they have a high-resistance layer at the boundary surface between the ceramic and the external electrode, achieved by a combustion process in which the glass components of the outer electrode melt. Thanks to electrode shaping, the electrode coating demonstrates exceptional bond strength.

The multilayer chip NTC thermistors are impervious to resistance changes in R2 and R3, forming a high-ohm layer at the interface of the semiconductive ceramics and substrate electrodes. The resistance change caused by reflow soldering and harsh environmental conditions is therefore minimal, and extremely accurate temperature measurement over long periods is possible.

The multilayer chip NTC thermistor delivers highly accurate values because the negative temperature coefficients of resistance (approx. -5%/°C) is ten times higher than for metal and around five times higher than for silicone temperature sensors.

NTC thermistors in use

• Battery management for Li-ion rechargeable batteries: NTC thermistor temperature sensors deliver critical temperature data from Li-ion rechargeable batteries. This information is crucial to keeping the battery in optimal condition during the charging cycle. In so-called battery management systems, they recognise the increase in temperature of the battery during charging and, with careful temperature management, protect the Li-ion batteries against potential hazards.

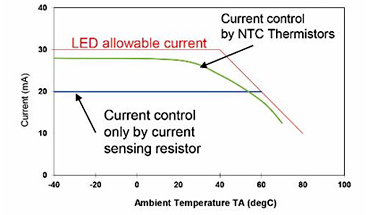

• LED lighting: When used in LED lighting, NTC thermistors ensure that the LEDs operate within an optimal temperature range and thus extend their lifespan. Moreover, the thermistors reduce the risk of loss of performance and prevent a decrease in luminous flux (lumens). NTCs also increase the efficiency of each individual LED, allowing a reduction in the total number of LEDs in lighting applications of up to 25 percent.

Situation

In many applications, temperature measurement is one of the most problematic processes. In the automotive industry, demand for NTCs has grown for applications including control units, electric pumps and compressors, LED lamps, batteries, audio systems, and alternative drive systems, amongst others. They are also used in industrial and domestic applications, e.g. for circuit compensation, in control applications and in battery management systems.

Solution and advantages

While the manufacture of precision thermistors was previously labour-intensive and time-consuming, Panasonic has succeeded in producing low-cost, replaceable glass thermistors on extremely stable, high-precision NTC chips.

These thermistors offer long-term reliability and stability and are suitable for use in harsh environments and in challenging thermal conditions. In addition, they have a high-resistance layer at the boundary surface between the ceramic and the external electrode, achieved by a combustion process in which the glass components of the outer electrode melt. Thanks to electrode shaping, the electrode coating demonstrates exceptional bond strength.

The multilayer chip NTC thermistors are impervious to resistance changes in R2 and R3, forming a high-ohm layer at the interface of the semiconductive ceramics and substrate electrodes. The resistance change caused by reflow soldering and harsh environmental conditions is therefore minimal, and extremely accurate temperature measurement over long periods is possible.

The multilayer chip NTC thermistor delivers highly accurate values because the negative temperature coefficients of resistance (approx. -5%/°C) is ten times higher than for metal and around five times higher than for silicone temperature sensors.

NTC thermistors in use

• Battery management for Li-ion rechargeable batteries: NTC thermistor temperature sensors deliver critical temperature data from Li-ion rechargeable batteries. This information is crucial to keeping the battery in optimal condition during the charging cycle. In so-called battery management systems, they recognise the increase in temperature of the battery during charging and, with careful temperature management, protect the Li-ion batteries against potential hazards.

• LED lighting: When used in LED lighting, NTC thermistors ensure that the LEDs operate within an optimal temperature range and thus extend their lifespan. Moreover, the thermistors reduce the risk of loss of performance and prevent a decrease in luminous flux (lumens). NTCs also increase the efficiency of each individual LED, allowing a reduction in the total number of LEDs in lighting applications of up to 25 percent.

With the various series of Panasonic NTCs, Schukat electronic meets the demand for NTC thermistors for a wide range of application areas: the automotive series (AEC-Q200 certified), the industrial series with standard tolerance of 3% or 5% and reduced tolerance of 1% or 2%, as applicable, and the consumer series. Small enclosure sizes as well as thermistors in SMD enclosures in a multitude of B-values and resistance values are available.

For questions about these resistors and in seeking out the right NTC thermistor for a particular application, our sales team is happy to advise you. These products are now in stock at Schukat.

With the various series of Panasonic NTCs, Schukat electronic meets the demand for NTC thermistors for a wide range of application areas: the automotive series (AEC-Q200 certified), the industrial series with standard tolerance of 3% or 5% and reduced tolerance of 1% or 2%, as applicable, and the consumer series. Small enclosure sizes as well as thermistors in SMD enclosures in a multitude of B-values and resistance values are available.

For questions about these resistors and in seeking out the right NTC thermistor for a particular application, our sales team is happy to advise you. These products are now in stock at Schukat.