The Problem

The demand for capacitors with high reliability, long life, stable performance and minimal ESR at low cost is increasing. In particular, the consumption of multilayer ceramic capacitors – MLCCs – is growing. The global production capacity of MLCCs is now far outstripped by the actual demands of the electronics market.

Solution and replacement example

To continue to meet the demand for capacitors, a search for alternative components is unavoidable. Polymer electrolytic capacitors, with their small size and cubic form, are the best choice when it comes to replacing for MLCCs. They even offer advantages over MLCCs.

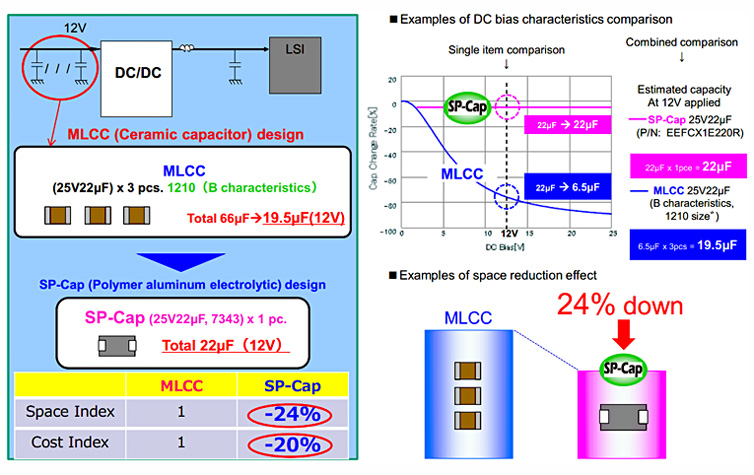

• Capacitance / DC bias: Polymer capacitors stand out with their high capacitance and outstanding bias characteristics. MLCCs do not achieve the same capacitance density as polymer capacitors and exhibit a strong capacitance dependence on DC bias. This means that their capacitance varies depending on the voltage applied. This can lead to a capacitance drop of more than 70% compared to the specifications given on the data sheet . For polymer capacitors, however, the capacitance does not vary significantly when the application voltage changes.

• ESR / ESL: Polymer capacitors have extremely low ESR characteristics. In addition, structural improvements mean they have low ESL. Polymer capacitors are highly resistant to drying-out of the electrolyte during their service life, and also to changes to their electrical characteristics at low temperatures.

• Temperature: With polymer capacitors, capacitance increases parallel to increasing temperature. With MLCCs, the temperature characteristics vary depending on type. They are, however, temperature dependent, require a low operating temperature and fail with increasing age.

Note:

Comparing the different characteristics is only partly helpful. Whether a capacitor is suitable also depends on the field of application. When designing circuits, other factors like cost, size and available space need to be considered.

• Especially with new developments and forthcoming redesigns, polymer capacitors represent a good choice. When replacing several connected MLCCs with one or two polymer capacitors, it is possible to save both space and money.

We can use the following target specs for replacing MLCCs with polymer capacitors: voltage lines from 16 to 35V, capacitance from 47μF to 560μF (high capacitance is one of the strengths of polymer capacitors, so the higher the better), and preferably B & D case sizes.

Tip: Find replacement capacitors easily

• In the search for a suitable polymer capacitor, Schukat provides a form in which users can enter the essential technical specifications of their MLCC application. Based on this, users then receive suggestions for a suitable replacement direct from Schukat, in collaboration with Panasonic.

Schukat can supply robust, long-lasting, safe polymer capacitors. Among producers, Panasonic is the only one to carry four different variants in their range: the OSCON, POSCAP, SP-Cap und Hybrid series. The solutions begin with a one-to-one replacement from type 1206.