| DE | EN | Contact | About us | Terms of Business | Imprint | Privacy & Cookies | Help | Newsletter | Registration | Login | |

|  |  |  |  |  |  |  |  |  |  |  |

| Home > News > Product News > Power Supplies, MeanWell News > ''More short-term power, Scotty!'' - Markt & Technik, Trend Guide Power Supply, July 29, 2022 | |||||||||||

''More short-term power, Scotty!'' - Markt & Technik, Trend Guide Power Supply, July 29, 2022Correctly sizing AC/DC power supplies for peak load applicationsLooking for an AC/DC power supply for an application whose peak power demand for brief intervals considerably exceeds the power it needs for normal operation? When it comes to power output and physical dimensions, you can very quickly find yourself looking at oversized, expensive products. For situations like this, Mean Well offers 300W power supplies that deliver much higher peak power.

How conventional power supplies behave when handling a peak load

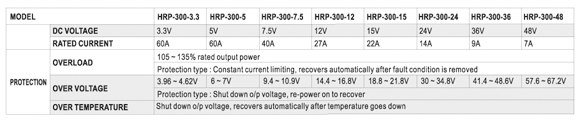

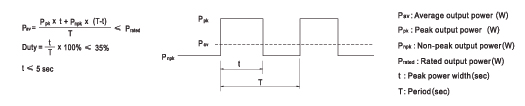

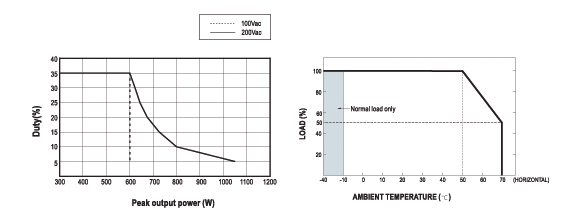

If, however – in the best case – the motor really does start in constant current mode, a 12V control unit powered in parallel alongside the motor would no longer function, because in overload/constant current mode the 12V nominal voltage at the power supply unit is reduced. And for machines such as grinders or in robotics, where a nominal speed has to be reached quickly and dynamic motor processes are called for, it isn’t enough to simply push the power supply unit to its limit. If a motor needs a significantly higher start-up current, one way to achieve this, of course, would be to use a power supply unit with correspondingly higher output power and thus prevent the overload protection function from kicking in and the nominal voltage from dropping. In our case, this would be possible, for example, with a power supply with double the power rating, such as the HRP-600-12 (also from Mean Well). However, this would result in an approx. 70 percent greater enclosure volume and a substantially higher purchase price. Peak-load capable power supplies A neater solution would be to choose a smaller power supply that is still able to deliver the required peak power: the HRP-300N3-12, for example. Like its sister model, the HRP-300-12, the nominal output power of the HRP-300N3-12 is 324W and it can also supply up to a maximum of 350 percent peak power, calculated from this nominal power. Whether the required peak power needs can be delivered for a particular application depends on the average load of the power supply, and can be calculated relatively easily using the formula shown in Figure 2. Keep in mind that the peak power can be maintained for a maximum of five seconds per cycle. It should also be noted that the average of peak and non-peak power drawn from the power supply unit can’t exceed its rated power, and the time ratio of peak power to non-peak power (t/T x 100%) should not exceed 35 percent. With these parameters in mind, the HRP-300N3-12 can supply peak power of up to 1050W. In determining the maximum peak power that can be drawn from the power supply unit, both the actual time ratio of peak power to non-peak power and the AC input voltage are crucial, while derating based on the operating temperature also plays an important role.

Example calculation In illustrating the power performance of the HRP-300N3-12 power supply unit with a theoretical example, we are assuming a buffer of 20 percent of the nominal output power. The power supply unit can thus be continuously loaded with a maximum of 260W by the end application, which can run on the 230V or 110VAC mains. The motor in use needs five seconds at 600W to get up to speed, roughly double the nominal power of the HRP-300N3-12. In the worst case, a motor restart can be expected after a motor stop on a 30-second cycle. The maximum expected operating temperature is below 50°C. • Input voltage is at least 100VAC • Peak power: max. 600W for max. 5 seconds • Total cycle time: 30 seconds or longer • Load cycle: t/T = 5/30 = 16.67% • Operating temperature < 50 °C Pav = (Ppk · t + Pnpk · (T-t))/T = (600 · 5 + 260 · (30–5))/30 W = 316.67 W In our example calculation, the average power is 316.67 watts, which is below the nominal power of 324 watts that the power supply has to provide. It would therefore be possible to operate the connected motor and restart it every 30 seconds with the increased power draw as described. If the power supply unit has to deliver higher peak power in similar applications, this would be feasible up to 1050W, based on mains voltage of 230V and taking into account the possible peak load duration, depending on the load, as shown in the graph below. Another advantage of the peak-load capable HRP-300N3-12: it has the same physical dimensions as its sister model, the HRP-300-12. So, despite delivering 600 watts or a maximum of 1050 watts peak power, the whole package is still as compact as a 300-watt supply. And the higher performance HRP-300N3-12 version is only slightly more expensive than the standard model, another reason to prefer it to an overpowered unit.

Features The HRP-300N3-12 described and pictured here is part of a family of power supplies with nominal power from 150 to 600W and peak power from 375 to 2100W that are primarily – but not exclusively – suited to use with electromechanical loads and motor applications. Their peak output current requires suitably dimensioned DC cables with a sufficiently large cross-section. The remote-sense function integrated into these power supply models can be used to compensate for the voltage drop through the DC connections during operation. The voltage drop through the DC connections, while undesired, is also unavoidable, but can be compensated for by up to 0.5V with this function, and the full required voltage can thus be supplied to the load. To remove the inevitable self-heating from the closed housing, which occurs as described in the "Efficiency advantage" section above, the units are fitted with a quiet, integrated fan. Based on the manufacturer’s specifications, this means that even at full load and an ambient temperature of 50°C, an expected operating lifetime of 50,000 hours can be assumed. While the built-in fan is already quiet, for acoustically sensitive applications the units are also equipped with an intelligent fan control that allows the fan to be regulated as required, thus keeping noise to an absolute minimum. To oversee operation, the power supplies have a DC-OK signal that can be monitored via a connected control system. Mean Well’s broad portfolio of high-quality AC/DC and DC/DC power supplies for a wide range of applications in industry, medicine, and domestic applications reflects their many years of experience in the development and production of power supplies. Schukat electronic has been among the largest European Mean Well distributors for over 25 years. (eg) '' The article was published in Markt&Technik Trend Guide Power Supply on July 29, 2022, see here. |